Introduction

Construction equipment is essential in today’s building projects. It boosts efficiency and enhances safety on job sites. From heavy machinery to specialized tools, choosing the right equipment can greatly influence a project’s success. This guide explores different types of construction equipment, their functions, and tips for selection and maintenance, making it useful for industry professionals and newcomers alike.

1. Classification of Construction Equipment

Construction equipment can be grouped into several categories based on their functions. Knowing these classifications helps in selecting the right tools for specific tasks.

1.1 Earthmoving Equipment

Earthmoving equipment is vital for tasks like site preparation and excavation. These machines move large amounts of earth, rock, and other materials.

Excavators

Excavators are crucial for digging and moving earth. They vary in size, from small mini-excavators to large hydraulic models. Key uses include:

- Digging Trenches: Ideal for foundations and drainage systems.

- Lifting and Moving Materials: With attachments, they can transport materials efficiently.

- Demolition: Larger models can break down structures with specialized tools.

Popular Brands: Caterpillar, Komatsu, and Hitachi lead the market.

Operational Tips: Proper training for operators is essential. Regular maintenance checks, like hydraulic fluid levels, ensure optimal performance.

Bulldozers

Bulldozers are powerful machines with broad blades for pushing soil, sand, or debris. They are used for:

- Site Preparation: Clearing and leveling land before construction.

- Grading: Ensuring proper drainage and flat surfaces for foundations.

- Clearing Obstacles: Removing trees and rocks on rugged terrains.

Maintenance Tips: Regularly check blade alignment and hydraulic systems to maintain performance.

Loaders

Loaders, especially front-end loaders, are versatile for loading materials. Their benefits include:

- High Efficiency: They quickly move and load large amounts of materials.

- Versatility: Attachments allow for various tasks, from loading to grading.

Selecting the Right Loader: Consider bucket size and horsepower based on project needs.

1.2 Construction Equipment

This category includes machinery and tools essential for various construction tasks.

Concrete Mixers

Concrete mixers are key for preparing concrete on-site. Their advantages include:

- Time-Saving: Immediate use of mixed concrete reduces delays.

- Quality Control: Greater control over mixtures ensures project specifications are met.

Usage Tips: Clean the mixer regularly and ensure operators follow safety protocols.

Cranes

Cranes are essential for lifting heavy materials. Types include:

- Tower Cranes: Fixed and used for high-rise buildings.

- Mobile Cranes: Moveable and versatile for different tasks.

Safety Protocols: Ensure operators are certified and conduct regular safety checks.

Forklifts

Forklifts are crucial for material handling. They help in:

- Transporting Materials: Quick movement over short distances.

- Loading and Unloading: Efficiently loading trucks to save time.

Maintenance Recommendations: Daily checks on tire pressure and hydraulic systems are vital.

1.3 Specialized Equipment

Specialized machinery is often needed for specific tasks.

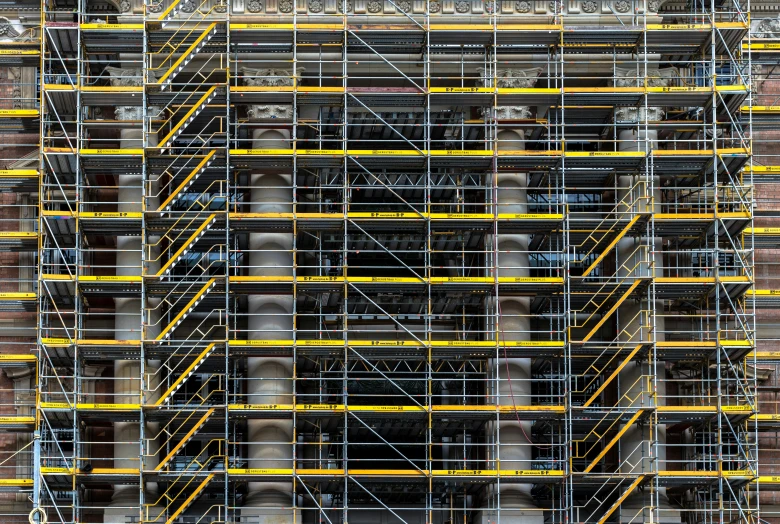

Scaffolding

Scaffolding supports workers and materials during construction. Key aspects include:

- Safety: Properly erected scaffolding prevents falls.

- Accessibility: Helps workers reach high areas easily.

Types of Scaffolding: Frame, system, and suspended scaffolding, each suited for different applications.

Compactors

Compactors compress materials to increase density, vital for stable foundations. Key functions include:

- Soil Compaction: Prevents settling of structures.

- Asphalt Compaction: Creates smooth road surfaces.

Operational Tips: Train operators in compaction techniques for the best results.

Pavers

Pavers lay asphalt or concrete on surfaces. Their advantages include:

- Precision: Ensures a uniform surface for roads.

- Efficiency: Automated pavers speed up the process.

Maintenance Considerations: Regular cleaning and inspections keep pavers functioning well.

2. Key Functions of Construction Equipment

2.1 Improving Construction Efficiency

The right equipment can reduce project time significantly. Efficient machines boost productivity, allowing teams to focus on other tasks. For example, excavators speed up foundation digging, facilitating quicker project progress.

- Automation: Many modern machines come with automated features that enhance precision.

- Multi-Functionality: Equipment that performs various tasks reduces the need for multiple machines.

2.2 Reducing Labor Costs

Efficient machinery lowers the need for extensive manpower. Using bulldozers and loaders allows fewer workers to accomplish more, resulting in cost savings.

- Labor Efficiency: Machines handle heavy lifting, reducing the workforce needed.

- Skilled Labor: There’s a growing demand for skilled operators, emphasizing the need for training.

2.3 Enhancing Construction Safety

Construction equipment includes safety features to protect operators and workers. Regular maintenance and safety protocols help prevent accidents.

- Safety Features: Modern machines often have shutoff systems and alarms.

- Training and Certification: Proper training for operators is crucial for safety.

- Regular Inspections: Frequent equipment checks help identify potential hazards early.

3. Choosing the Right Construction Equipment

Selecting the right equipment is vital for project success. Consider these factors:

3.1 Selecting Based on Project Needs

Different projects require different equipment. For example, residential projects may need smaller machines, while commercial ones might require larger equipment.

- Project Scope: Understand the project’s size to determine the necessary equipment.

- Site Conditions: The nature of the site influences equipment choice.

3.2 New vs. Used Equipment

When choosing between new and used equipment, consider:

- Cost: New machines are pricier but come with warranties; used ones are cheaper but may need more maintenance.

- Condition: Assess used machinery carefully to avoid surprises.

3.3 Renting vs. Buying

Renting is beneficial for short-term projects, while buying may be more cost-effective for long-term use.

- Rental Advantages: Access the latest equipment without upfront costs.

- Ownership Benefits: Owning equipment can save money over time.

4. Maintenance and Care of Construction Equipment

4.1 Importance of Regular Inspections

Regular inspections maintain equipment functionality and safety. Implement a schedule for checks to catch issues early.

- Daily Checks: Operators should inspect equipment for leaks and fluid levels before use.

- Scheduled Maintenance: Follow manufacturer recommendations for servicing.

4.2 Common Issues and Solutions

Knowing common equipment failures aids in troubleshooting. For example, hydraulic leaks in excavators can often be fixed by replacing seals.

- Preventive Maintenance: Regular oil and filter changes can prevent many issues.

- Training for Troubleshooting: Teach operators to recognize potential problems quickly.

4.3 Managing Maintenance Records

Keeping detailed maintenance records helps track repairs and ensures efficient operation.

- Digital Maintenance Logs: Use software for easy record-keeping.

- Scheduled Reviews: Regularly review records to identify patterns needing attention.

5. Innovations and Future Trends in Construction Equipment

5.1 Automation and Smart Technology

The industry is moving towards automation, with machines equipped with GPS and AI technology, improving accuracy and reducing manual labor.

- GPS Technology: Modern machines use GPS for precise grading, reducing waste.

- AI Integration: AI analyzes project data for optimal resource use.

5.2 Environmentally Friendly Equipment

There’s a rising demand for eco-friendly construction equipment. Manufacturers are developing machines that use alternative fuels and have lower emissions.

- Electric and Hybrid Equipment: New machines reduce noise and carbon footprints.

- Sustainable Practices: Companies are adopting practices that minimize waste.

5.3 Application of New Technologies

Innovative materials and technologies, like 3D printing, are transforming construction.

- 3D Printing: Speeds up building processes and improves precision.

- Drones: Used for surveying, enhancing project management with real-time data.

6. Market Analysis of Construction Equipment

6.1 Current Market Trends

Demand for construction equipment is influenced by economic growth and infrastructure development. Understanding these trends is vital for smart purchasing.

- Economic Indicators: Monitor housing starts and infrastructure spending for insights.

- Technological Advancements: Stay updated on the latest machinery innovations.

6.2 Major Brands and Product Comparisons

Researching brands helps identify strengths and weaknesses. User reviews and expert opinions can guide decisions.

- Brand Reputation: Established brands are often seen as reliable.

- Product Offerings: Compare specifications and warranty options to find the best fit.

6.3 Future Market Predictions

The construction equipment market is expected to grow as more projects arise globally. Companies should prepare for changes in demand and technology.

- Emerging Markets: Increased infrastructure investment in developing countries will drive demand.

- Sustainability Trends: The push for eco-friendly practices will create new opportunities.

Conclusion

In summary, construction equipment is vital to the building process, affecting efficiency, safety, and overall project success. Understanding equipment types, functions, and maintenance is essential for industry professionals. As technology advances, staying informed about trends will help make the best choices for projects.

By investing in the right equipment and practicing good maintenance, construction professionals can enhance productivity and create safer job sites. The future looks bright for construction equipment, with new technologies and a focus on sustainability making it an exciting time to be in the industry.